Zero emission with extended range.

Xcelsior CHARGE FC™ is New Flyer’s next generation, zero-emission hydrogen fuel cell-electric bus. It delivers longer range, better energy recovery and is smart city capable, making it the most advanced hydrogen fuel cell-electric bus in North America.

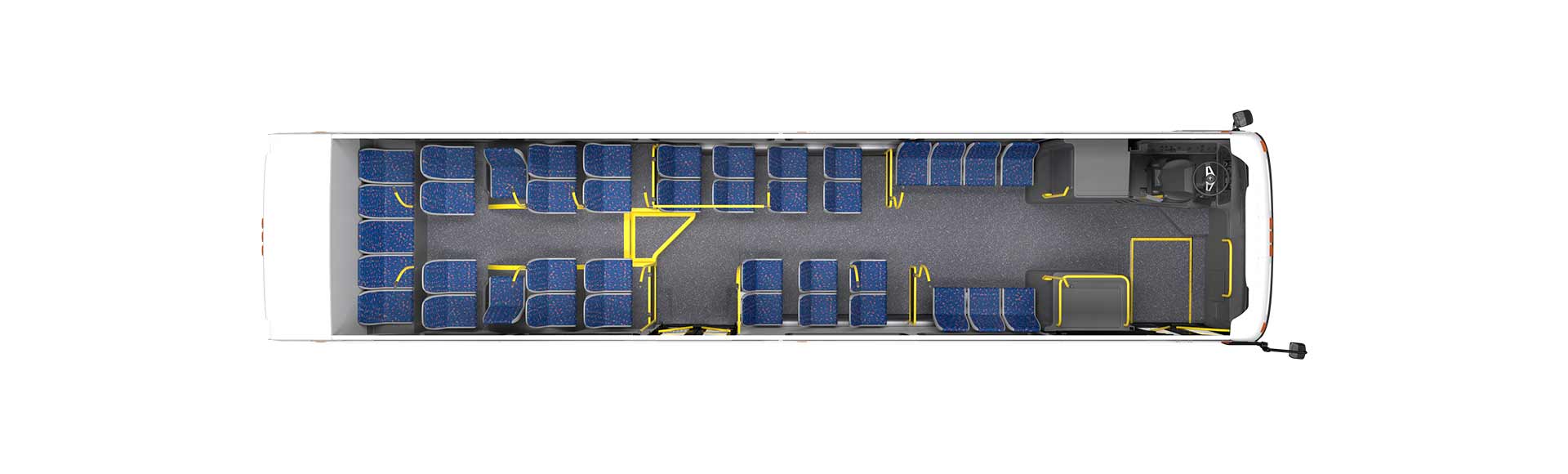

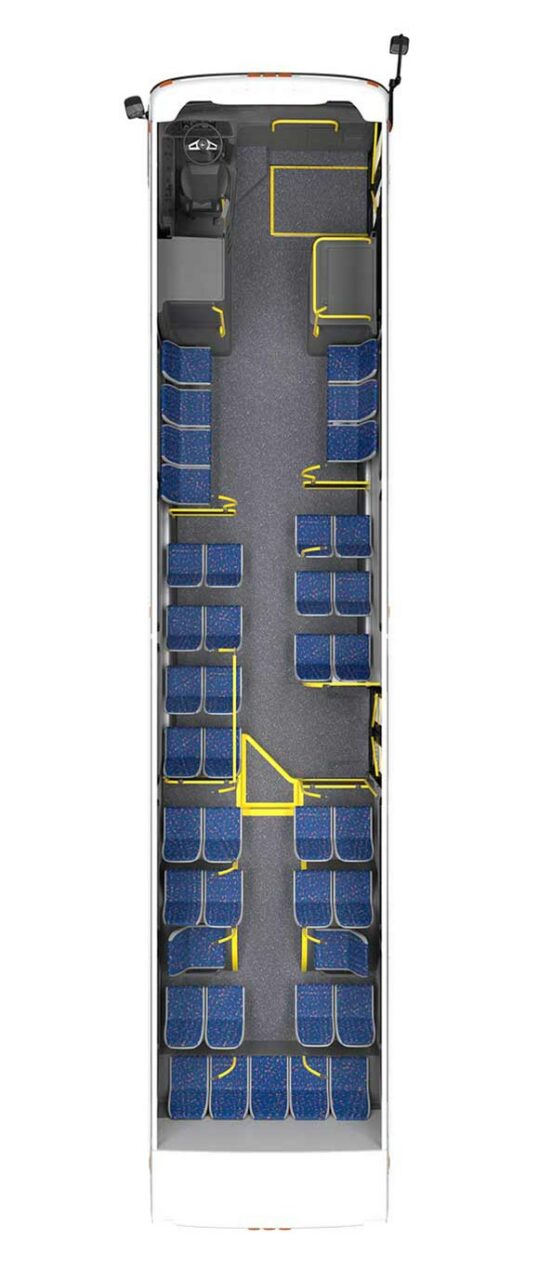

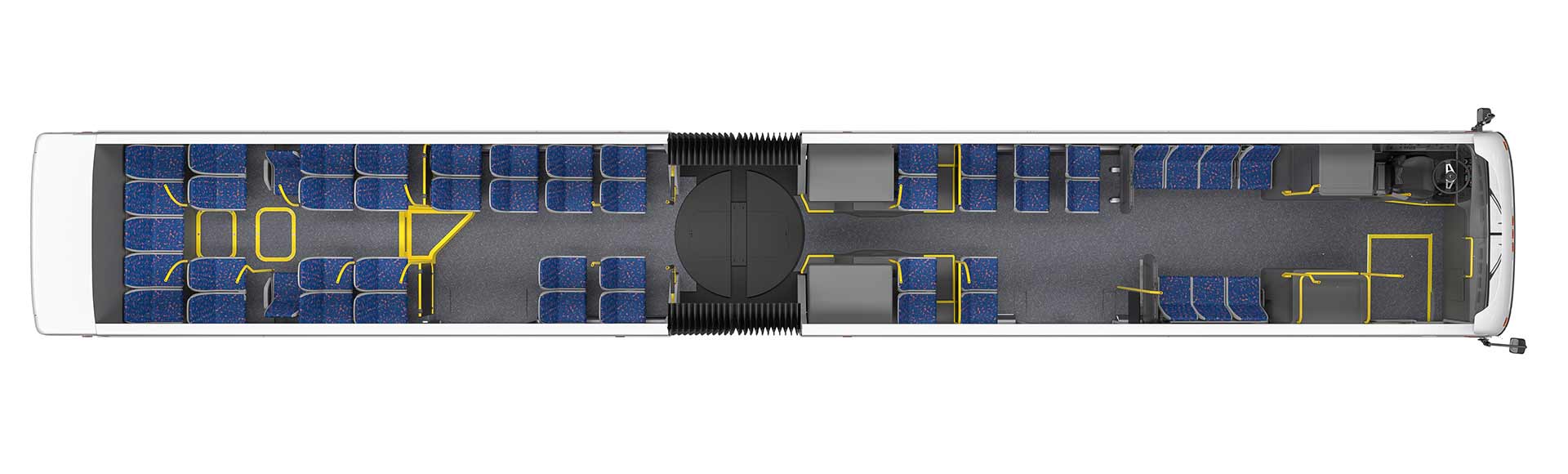

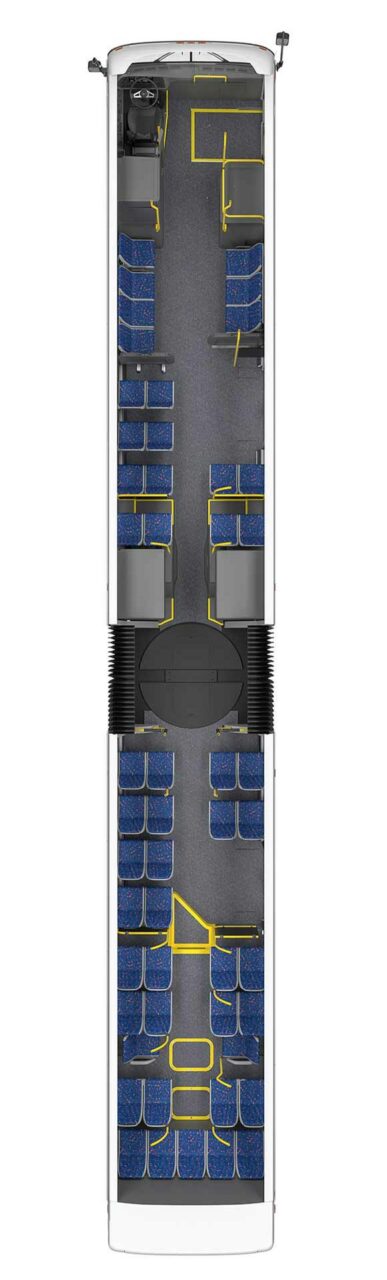

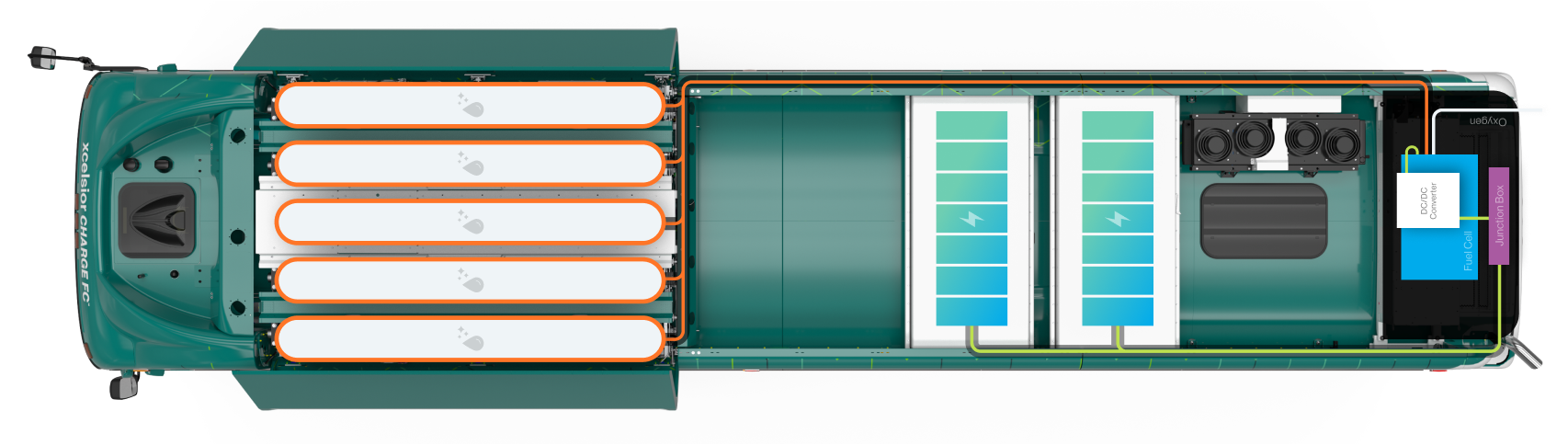

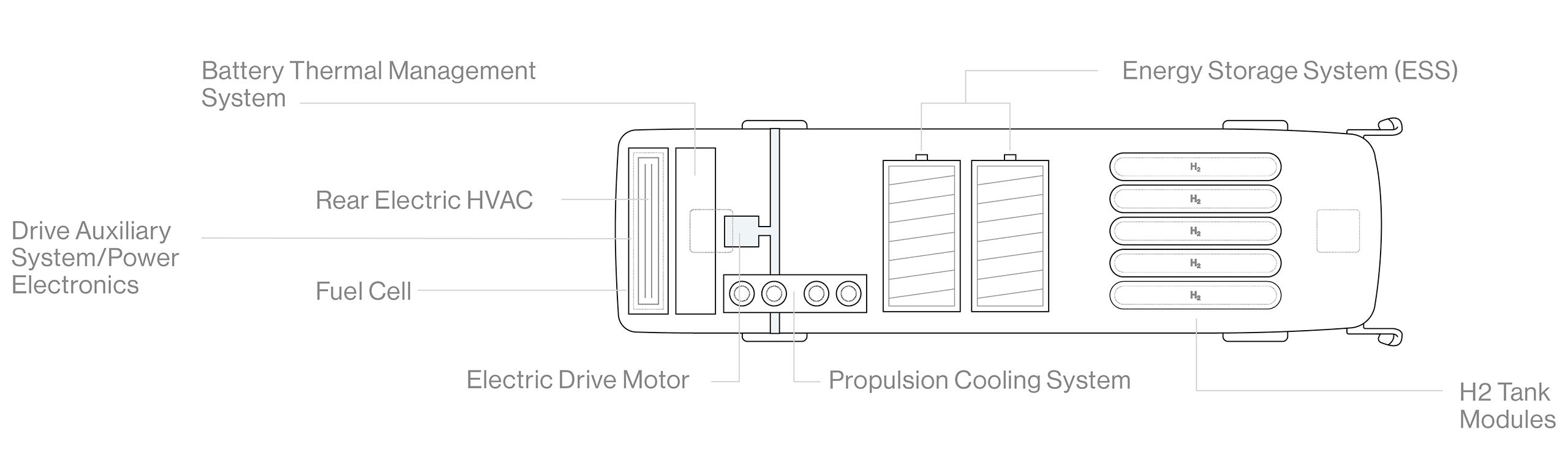

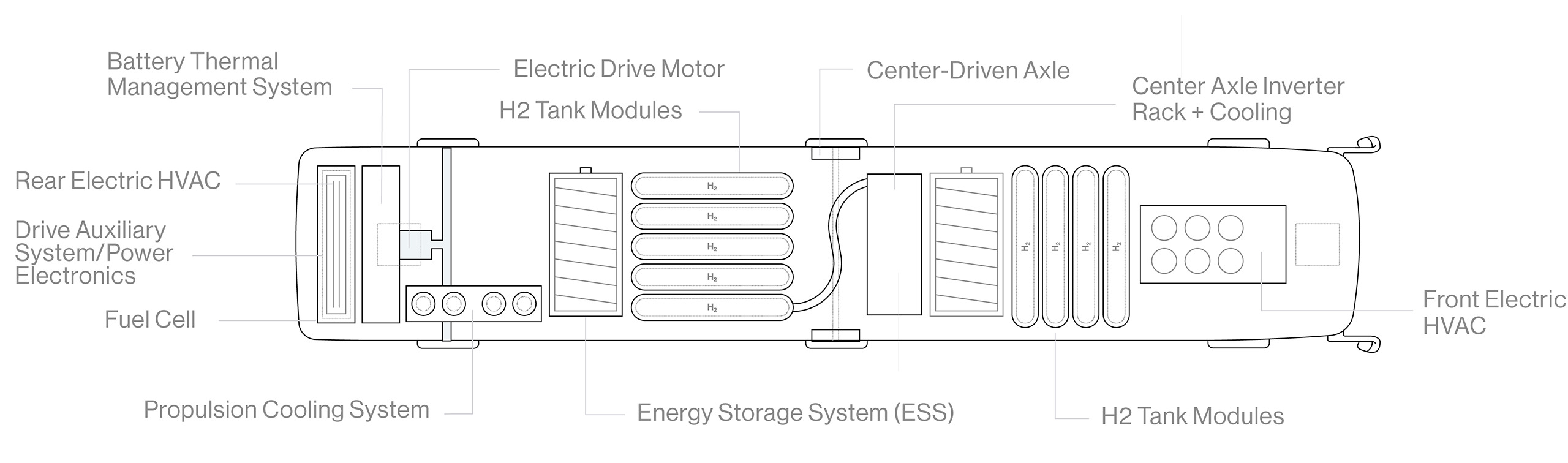

Floorplans

Decades of innovation.

Built on the proven Xcelsior® platform with over 16,000 buses delivered to date, New Flyer’s battery-electric and fuel cell-electric models have surpassed over 15 million electric vehicle service miles.

Drawing upon more than 20 years of experience producing fuel cell-electric buses for North American operators, New Flyer has applied the best of zero-emission design and innovative fuel cell technologies to develop its most advanced hydrogen fuel cell-electric bus yet.

Built on the proven Xcelsior® platform.

-

Extended Range

Travel 370+ miles on a single refueling with no off-board electric recharging.

-

Fast fill time ranging from 6-20 minutes (depending on bus model and operating conditions)

-

Avoid 85-135 tons of greenhouse gas per year from tailpipe emissions compared to a diesel bus

New high-performing technologies.

Xcelsior CHARGE FC™ incorporates four distinct and new high-performing technologies:

- Ballard Power Systems new high-performing fuel cell power module, called FCmove™-HD+

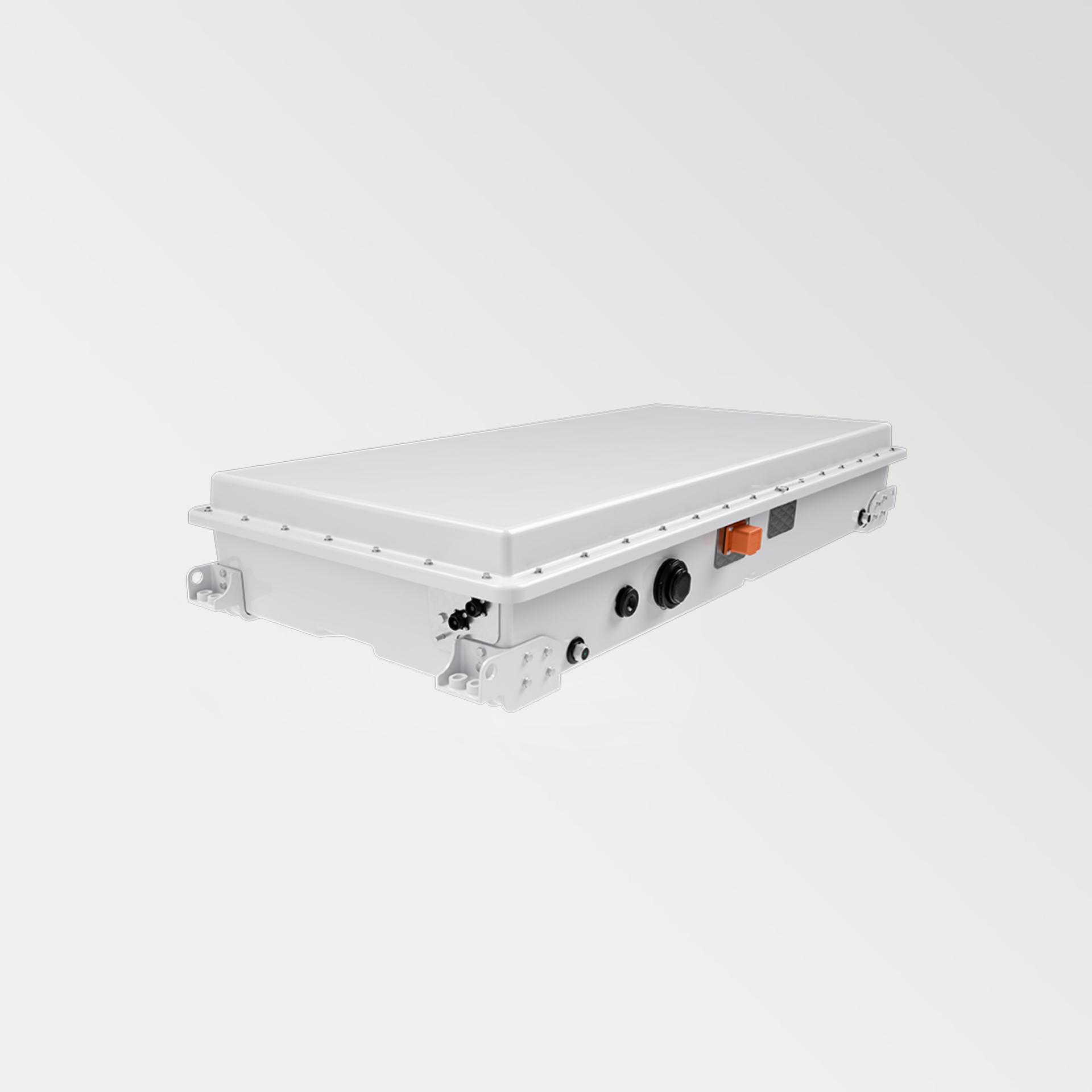

- New battery packaging designed and developed by New Flyer

- The newest, high-power, rapid-charge batteries

- Accelera™ by Cummins ELFA 3, a new innovative traction drive system

Fuel cell power module.

More efficient and streamlined battery enclosure.

High-grade Accelera™ by Cummins traction system.

The newest high-power batteries.

How it works.

A fuel cell is a device that converts chemical energy into electric energy. A series of chemical reactions splits hydrogen into protons and a current of electrons and then combines them with oxygen, which produces water and heat. The flow of electrons is the electric current. The electric current is used to power the batteries and ultimately power the bus.

Fuel cells produce electricity without combustion, which means that, unlike internal combustion engines, they generate little (if any) noise, vibration, air pollution, or greenhouse gasses and operate at high efficiency over a wide range of loads.

High-performance bus.

.

ECO friendly.

Hydrogen is clean, abundant, and can be reformed into hydrogen from natural gas (methane) or created from renewable sources such as wind or solar energy through electrolysis.

The Xcelsior CHARGE FC™ will avoid 85-135 tons of greenhouse gases per year from tailpipe emissions compared to a traditional diesel bus.

.

Quiet in operation.

With the absence of a traditional internal combustion engine and its related mechanical and exhaust noises, passengers will love the significantly quieter ride provided by the nearly silent electric traction motor:

.

Qualifies for federal funding.

Both the 40-foot and 60-foot models meet the Federal Transit Administration Model Bus Testing Program at Altoona, Pennsylvania. New Flyer remains the only North American manufacturer to offer both 40-foot and 60-foot fuel cell-electric models that qualify for federal funding.

Dual-sided Boarding Option.

New Flyer offers an optional three-door configuration that includes a street-side door for bus rapid transit (BRT) application. Available on all Xcelsior® 40-foot and 60-foot buses, the three-door bus design ensures faster, more flexible BRT platform boarding and enhanced passenger experience.

Benefits of dual-sided doors:

- A center median can become a platform with a single station for both directions

- Curb lanes are freed up, making for an uninterrupted flow of vehicle traffic along the right-side curbs

- Left-side doors bring new options for one-way streets or dedicated right-of-ways

- New designs for BRT stations are now possible with faster boarding and de-boarding

.

Video.

Quick measurements.

|

|

*Passenger capacity shown reflects standard configuration. Capacity may change dependent on custom design and components used.

Fueling.

Equipped with either or both TN1 or TN5 fill receptacles or a multi-fill port configuration. Receptacles can also be equipped with IR transmitters or hardwired communication ports to support fast filling at smart fill stations.

Lightweight Type 4 HGV2 tanks with 95% usable capacity.